Storage Guide for Event Centers, Hotels, Casinos, & Other Venues

April 18, 2024

Lightweight and durable, our commercial folding tables, banquet chairs, staging, and other event furnishings come with an industry-leading warranty.

ABS plastic, linenless laminates, & more!

View All

#1 in comfort. Gorgeous styles.

View All

Modern styles for all occasions.

View All

Faux teak, wicker, & rope styles.

View All

For fast, organized event setup.

View All

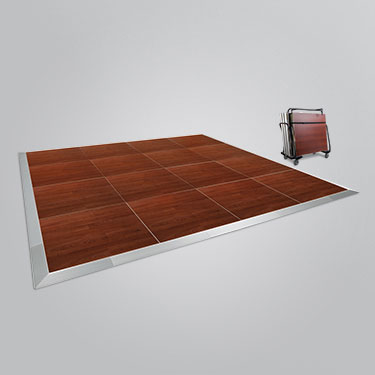

Magnetized, tool-free assembly.

View AllWhen you select MityLite folding chairs and tables, you can count on durability and quality. We don’t cut corners, and it shows.

Our industry-leading warranties are unbeatable in the commercial furniture industry. For example, our gorgeous Reveal Linenless Tables feature a 15-year warranty, which ensures that your folding tables will stand up to heavy commercial use.

Talk to an expert! We’re here to help with quotes, questions, and more. Find your rep today.

Create a bespoke look with 1000s of fabrics, finishes, and materials.

Based in Orem, Utah, we create award-winning commercial furniture. Learn more About Us.

At MityLite, we live and breathe commercial furniture! Whether you need product recommendations, replacement parts, or you’re ready to place an order, we’d love to hear from you.

Find Your Sales Rep

We’re with you every step of the way, from getting a quote, to getting fabric samples, to scheduling your furniture delivery day!

Once you find the products you want, submit a quote request directly from the product page. Your request will be routed to the Sales Rep who covers your area.

1

Your Sales Rep will reach out to you by email or phone (according to your preference) and give you a quote with pricing information.

2

Double check the quote from your Sales Rep to verify colors, sizes, and billing and shipping information. Then, submit the order. If needed, submit your tax-exempt certificate at this point in the ordering process.

3

You will pay for your order securely through our website. In the top menu bar, click on Customer Service and in the drop-down menu, select Pay Online. Enter the payment amount, invoice number, and other payment information.

4

We offer several different types of delivery to your facility! Talk to your Sales Rep and read our Delivery Instructions for more information.

5

April 18, 2024

April 9, 2024

April 9, 2024

April 3, 2024